Robot automation of assembly processes

Mounting of items by means of a robot requires that the robot be able to grip 1 item that is correctly facing so that it can be placed in the mounting position.

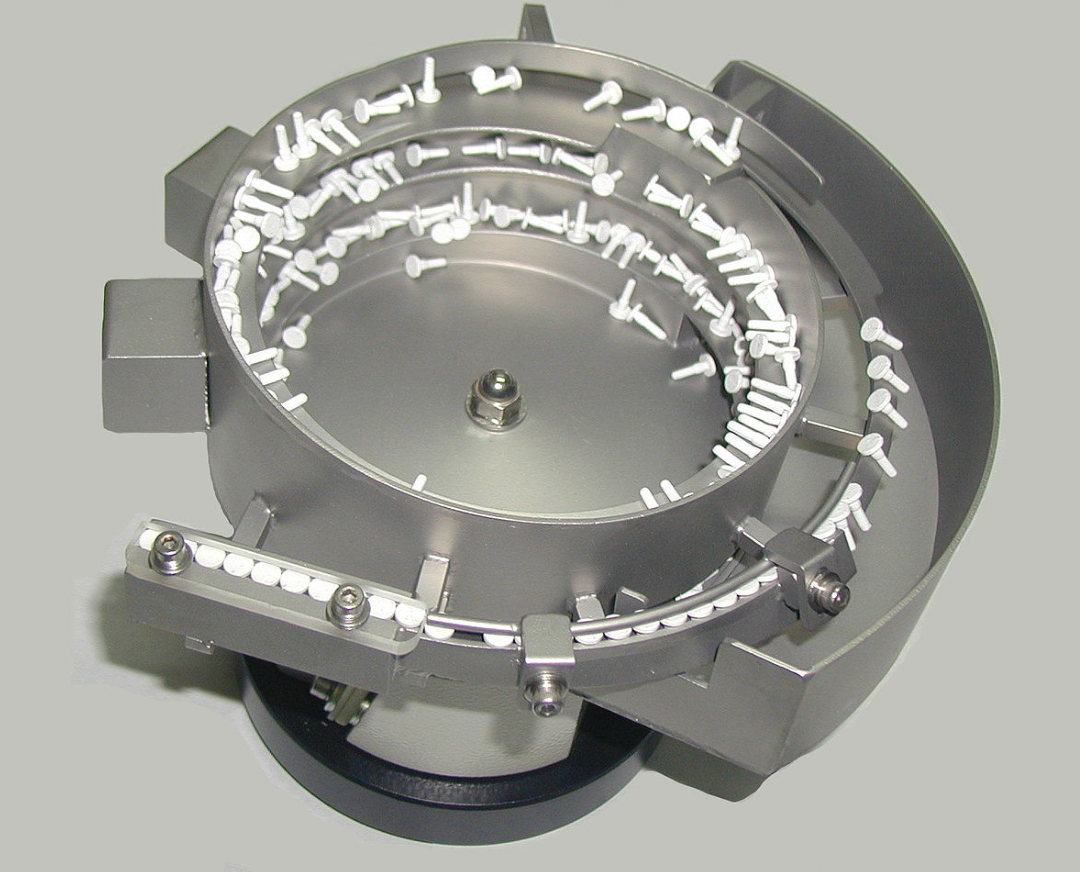

In most systems, it is solved by pouring the objects into a bowl feeder. Here, the items are vibrated around and at "traps", the items that turn wrong is sorted out.

Bowl feeders are noisy due to vibrations, and they are very sensitive to small changes in the weight and tolerances of the items, and they are difficult to ajust to variations in the items.

A less complex and less noisy solution is step feeder. A step feeder consists of stairs moving up / down, pulling up a smaller number of items from a supply container.

The items that come up are then guided by sliding rails, possibly with vibrator or small conveyors. The items that are positioned wrong are removed using "traps".

So only correct oriented parts reach the robot so that it can grip the item and move and place it in the right position.

In addition, the step feeder can often be fitted in smaller space, so that ergonomically better loading of items can be made, or the assembled machine can be less bulky.

Aplica designs step feeders to fit the robot system. It ensures fast delivery, short commissioning and high efficiency.